A Green Partner for the Environment

ESG

Green Shopping Program

Following the development of e-commerce technology, the convenience of online shopping has brought about large-scale changes in consumption patterns. In the post-pandemic era, consumers have become more dependent on online shopping, leading to the booming development of e-commerce. In 2023, PChome delivered more than 11.59 million boxes. To reduce the environmental impacts of e-commerce, PChome launched the Green Shopping Program in 2019, with four aspects at its core – green packaging, green transportation, green warehousing, and electronic green shopping. We link together suppliers and consumers through cooperation and innovation, and jointly create a sustainable value chain for online shopping.

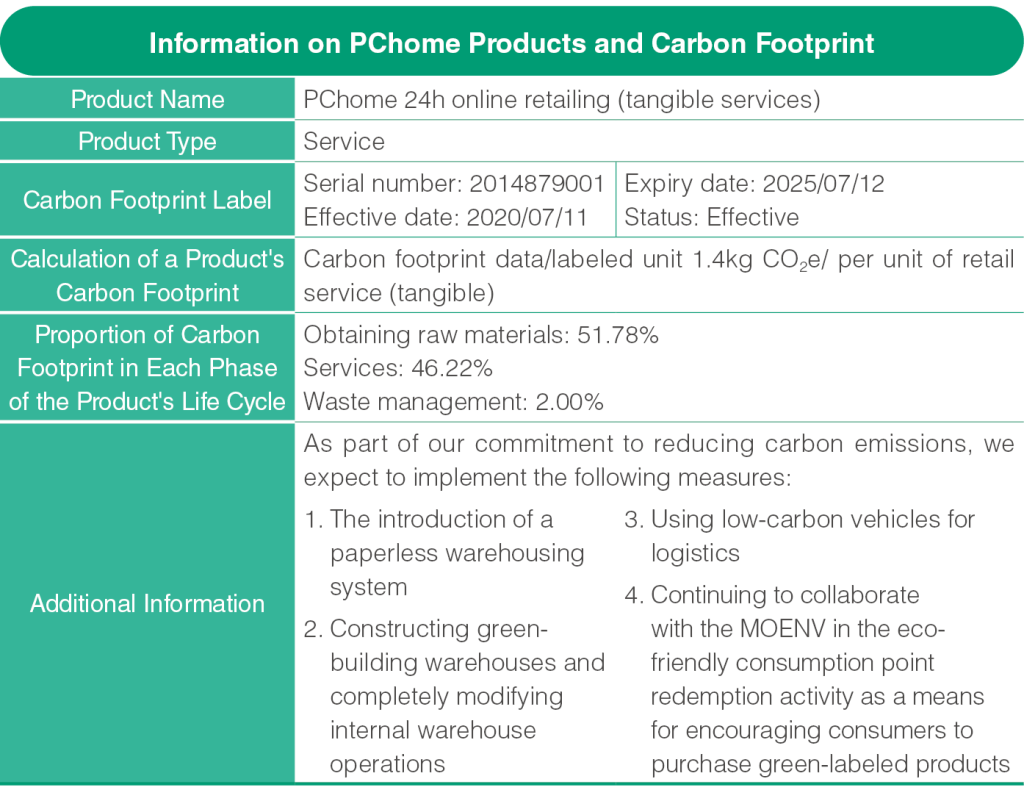

PChome 24h Online Retailing (Carbon Label)

To transparently disclose the carbon emissions from using online shopping services, PChome examined the carbon footprint involved at each stage in the life cycle of online retail services and analyzed product-related services (product inspection, packaging, etc.), environmental services (official website, domains, servers, cross-platform connectivity, etc.), and logistics services (pickup, delivery, returns, exchanges, etc.), so as to acquire quantified data and further implement carbon reduction strategies. PChome was the first major integrated online shopping platform in Taiwan to receive the Taiwan Carbon Footprint Label from the Ministry of Environment, Executive Yuan. At PChome, we encourage consumers to prioritize carbon footprint-labeled products to showcase their green influence as consumers. We also invite numerous SMEs and supply chain partners to engage in energy conservation and carbon reduction with us and usher in a new era of low-carbon e-commerce. PChome also actively applies for the Carbon Reduction Label to demonstrate our commitment and determination towards carbon reduction.

Green Packaging

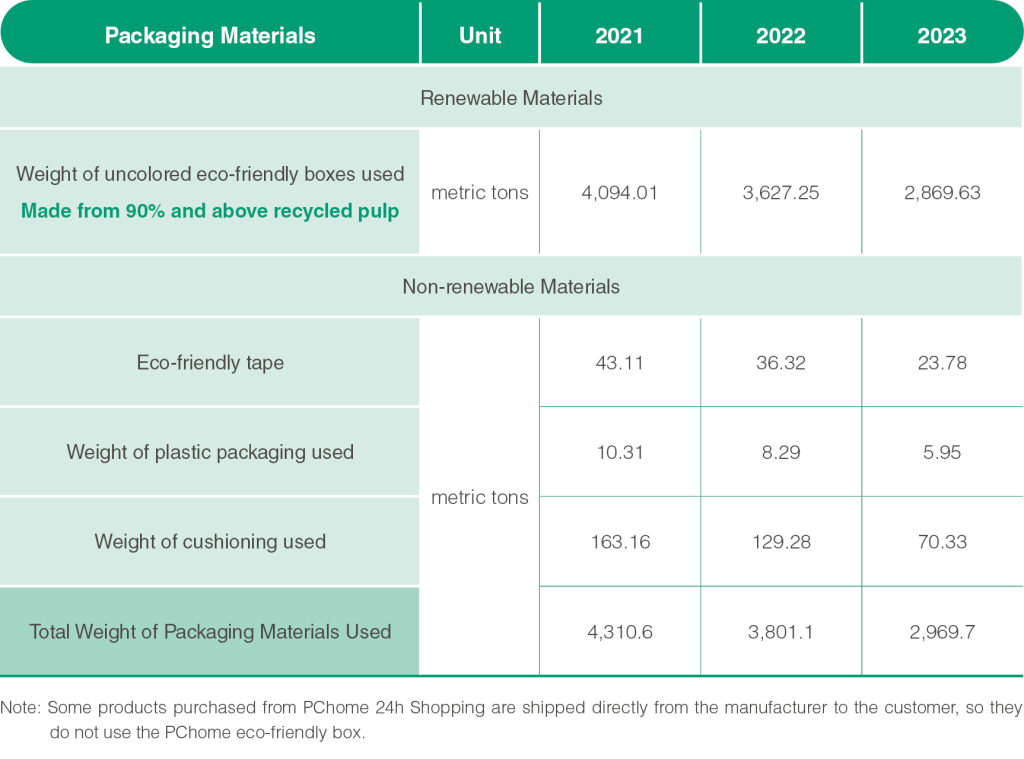

To ensure that goods are delivered to consumers intact, safe, and reliable, packaging is crucial in online shopping services. However, the traditional online shopping model consumes a large amount of disposable packaging materials, which puts a considerable burden on the environment. To realize eco-friendly management and maintain the sustainability of forest resources, PChome has adopted four strategies for packaging improvement: implementing recyclable packaging, comprehensively using boxes made from recycled pulp for delivery, reducing the use of single-use packaging, and selectively switching to recyclable cushioning. We are actively working with manufacturers of packaging materials in designing and developing more sustainable green packaging materials. Since 2019, we have designed 31 new types of eco-friendly boxes. By establishing rules for using consumables and adjusting the shipment process of warehouses, we have significantly reduced the use of consumables and cushioning, including paper boxes, cushioning, and tape, which has effectively reduced the impact of online shopping packaging materials on the environment.

PChome’s eco-friendly boxes boast the following features

- Completely replaced old boxes with eco-friendly boxes, all boxes used for shipping and delivery use 90% recycled paper and recycled pulp, effectively reducing the number of trees cut down

- The high-density paper increases the reuse rate and lowers carbon emissions

- The boxes maintain the original color of the pulp, the appearance of boxes was redesigned in 2023 and reduced the printed area by 40%, thus reducing ink use

- The ink printed on small external areas of the boxes is made from RoHS compliant, eco-friendly, and water-soluble ink

More than 90% of PChome’s shipments and deliveries use eco-friendly boxes in their original color. Compared with commonly used traditional boxes, on average one box can reduce carbon emissions by 8.2%. Each kilogram of recycled boxes used can reduce emissions by 5.29kg CO₂e (Note 1). As of the end of 2023, carbon emissions were reduced by more than 78,000 tCO₂e, which is equal to 202x the carbon adsorption capacity of Da’an Forest Parks in one year (Note 2). In addition, PChome also continues to optimize the design of auxiliary materials, and introduced the easy-to-tear tape to use with eco-friendly boxes in 2020. The tape is made of hydrophilic acrylic and ecofriendly adhesive, making it eco-friendly, safe, easy to tear, RoHS compliant, US FDA-approved, non-toxic, and can safely come in indirect contact with food. This eco-friendly tape is used with boxes, allowing consumers to swiftly remove the tape when recycling boxes. The tape does not leave any residual adhesive, which helps achieve the goal of 100% recycling, promoting eco-friendly practices. (Note 1: Referenced statistics of Longchen Paper & Packaging Co., Ltd. and Taiwan Paper Industry Association, Note 2: calculated based on the annual carbon absorption of Da’an Forest Park of approximately 389 tons)

(GRI301-1, GRI301-2)

In 2019, PChome responded to the E-Shopping Packaging Reduction Program launched by the Ministry of Environment (formerly named the Environmental Protection Administration) and submitted an action plan aimed at the three main goals of reducing packaging, introducing eco-friendly materials, and recycling packages. PChome was awarded the Online Shopping Packaging Reduction Seal by the Ministry of Environment, recognizing the goal achievement progress of PChome.

The Ministry of Environment implemented “restrictions on targets of usage and implementation methods for online shopping packaging starting from July 1, 2023, requiring all online retail industries to meet the following specifications: Paper packaging materials must be made of at least 90% of recycled papers, plastic packaging materials must be made of at least 25% of recycled materials, and materials containing PVC must not be used. PChome has taken the lead in adopting related measures, using eco-friendly packaging materials that are made of 25% recycled materials. In terms of paper packaging boxes, we have achieved 90% and above recycled paper use, which exceeds the regulatory requirements. In the future, PChome will continue optimizing the average weight reduction rate of packaging materials, effectively reduce packaging weight from the source, and become a model for online shopping companies.

In addition to improving packaging materials, PChome has further expanded the application scope of the “box number recommendation system” to all warehouses in 2021. The packaging recommendation for multi-item orders is optimized through AI and big data, improving the overall efficiency of packaging materials used for shipping. Box numbers are recommended based on the criteria of “minimum number of shipping boxes” and “the optimal box size,” recommending size-appropriate packaging boxes to reduce the number of boxes shipped and achieve the goal of reducing the use of boxes and packaging materials. The average match rate was 54.9% in 2023. Based on our own estimations, compared to manual judgment in the past, the smart box number recommender system is projected to reduce the number of boxes used per month by 5%. The boxes are estimated to save more than NT$1.3 million in packaging and logistics per year. In addition, the load factor of a logistics vehicle can be increased through efficient box space utilization, thus increasing shipping efficiency and reducing the carbon footprint of each delivery. In the future, PChome will continue optimizing the accuracy and combine the requirements of the Ministry of Environment program to incorporate the weight reduction goals of packaging into the smart box number recommender system to reduce the usage of packaging materials and packaging waste from online shopping.

Green Logistics

PChome strives to develop a more sustainable logistics and distribution system to actively respond to the impact of logistics and transportation on the environment. As the logistics and transportation business expands, PChome established a reliable solution for long- and short-distance transportation by founding a whollyowned subsidiary logistics company in 2018, PChome Express Co., Ltd., and was the first e-commerce platform to venture into last mile logistics. We continue enhancing our warehousing and delivery service capabilities.

Starting from 2020, PChome has actively responded to the “Green Shopping Program,” focusing on transforming the fleet mainly consisting of trucks and scooters towards green transportation. So far we have purchased 13 e-scooters and formed the PChome Green e-Scooter Fleet. Districts of Taipei and New Taipei with high population and delivery densities are covered by our e-scooters in the initial phase. This not only successfully reduced the fuel consumption and indirect carbon emissions generated from logistics, but also reduced operating costs and improved distribution efficiency. Each e-scooter is estimated to reduce carbon emissions by 1.33 tCO₂e per year, and the Green e-Scooter Fleet is expected to reduce carbon emissions by 17.29 tCO₂e per year. We plan to obtain 2 more electric scooters in the third quarter of 2024, in hopes of reducing carbon emissions by another 2.66 tCO₂e per year. In the future, we will replace gaspowered scooters with e-scooters each year based on their service life. The goal is to increase the proportion of e-scooters to 100% before 2030.

Our general logistics management strategy is to require unit supervisors to periodically inspect scooters for abnormal fuel consumption rates. Abnormal scooters, those with poor transportation routes, and high idle speeds are corrected to reduce the idling rate of our logistics fleet. In addition, the “Best Route Arrangement System” was launched in September 2023. The system applies AI to calculate the best route, improving the efficiency of “last mile delivery”, while achieving goals to reduce energy consumption and carbon emissions. Other than our own logistics fleet, PChome also realizes the carbon management guidelines in our supply chain and prioritizes logistics companies with green transportation as our partners, such as logistics services providers with electric vehicles. At the same time, existing distribution and logistics partners are also encouraged to expand their green energy fleets. By 2023, logistics service providers that we partner with are expected to invest in 18 e-scooters for delivery.

On the other hand, we share remaining transportation capacity through industry cooperation, improve transportation efficiency and flexibility, and achieve green transportation. For example, when a scooter is not fully loaded and the delivery routes are similar, we use Uber Direct to share the same scooter with peers for product delivery. By sharing transportation resources, we can use resources more efficiently, reduce empty scooters, reduce energy consumption, reduce traffic congestion and carbon emissions, and reduce the impact on the environment.

Green Warehousing

To ensure sustainable operations and reduce negative environmental impacts, PChome continues to optimize product configuration through AI and big data, and introduces highly automated warehousing equipment to reduce manual work. PChome also actively optimizes the picking and packaging efficiency of overall warehousing. With the adoption of shuttle racks and AGVs in 2023, the proportion of automated shipments accounted for 30% of annual shipments, an increase of 200% compared to 2022.

The rack areas of the automated warehouse do not require lighting, realizing a storage environment without any lighting, saving electricity, and indirectly reducing carbon emissions. Furthermore, warehousing operations adopt a product-to-worker strategy to reduce the walking distance and the workload of put-away and picking tasks, thus increasing the reliability of the manual workforce. This strategy reduces manual labor for put-away and picking tasks by 50-60%, while maintaining the same order volume and achieving a work efficiency equivalent to manual warehousing. This is expected to reduce overall manpower by 30-35%. In addition, we ventured into automated processes such as order picking optimization, inventory pre-positioning, storage location allocation optimization, smart picking, and packaging optimization. We utilize the advantages of automated warehousing to increase the efficiency of storage space use, and significantly improve shipment efficiency.

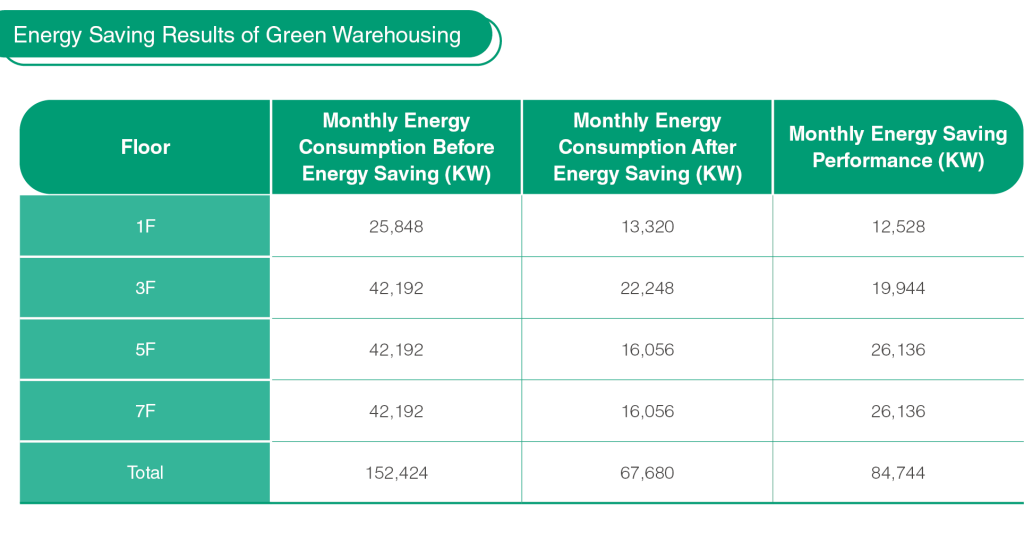

In terms of improving warehousing hardware equipment, PChome continues to replace old equipment. Currently, over 90% of the 80,000 ping warehouse area uses LED lighting to save electricity. Compared with incandescent light bulbs, energy-saving LED lighting reduces energy consumption by 50-70%, greatly improving energy-saving benefits. After the energy-saving project is implemented, it is expected to save 84,744 kW of electricity every month. We will continue to improve energy-saving measures, and plan to turn off non-essential power sources in working areas at certain times to achieve better energy-saving results.

In addition, we expect to make full use of warehousing space resources in the future, attract investments to assist e-commerce operators in need, and share warehousing resources. This cooperation model can not only reduce costs, but also promote resource sharing and reduce waste.

Linkou A7 Intelligent Logistics Park

As e-commerce matures and its market share in the retail industry steadily increases, PChome began to face challenges of warehousing and logistics due to the wide variety of goods and the huge volume of orders. To this end, starting in 2019, PChome planned the Linkou A7 Intelligent Logistics Park as a smart warehouse system that combines automation and AI technology. PChome expects to unify all warehouses currently scattered around Taoyuan with A7. This large-scale expansion would increase the efficiency and quality of logistics and provide consumers with a superior shopping experience in order to expand clientele. Adopting centralized management effectively controls logistics costs and expenditures.

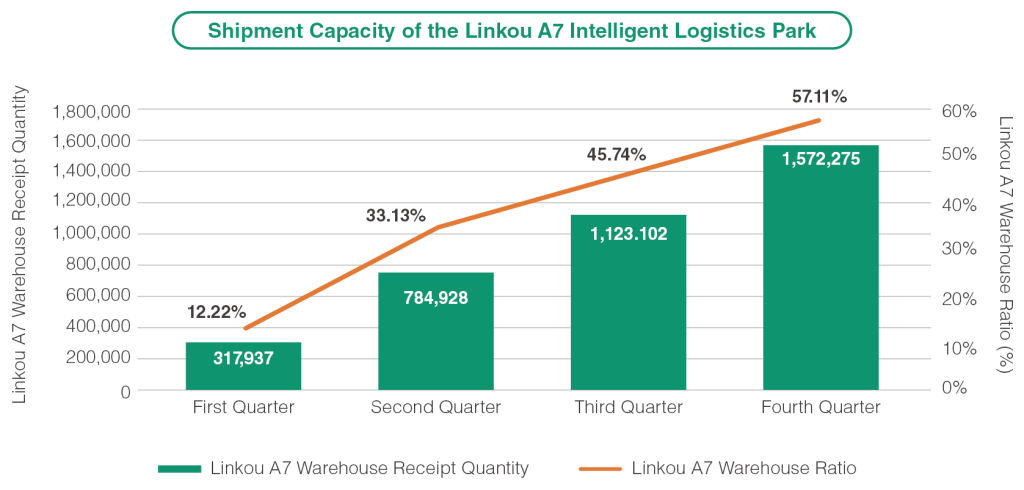

The Linkou A7 Intelligent Logistics Park is located in a designated industrial development zone near Station A7 on the Taoyuan Mass Rapid Transit System. The warehouse is developed by Chunghwa Post and has an area of around 45,000 ping and serves as an integrated logistics center comprising four main warehouse floors. The Linkou A7 Intelligent Logistics Park was specially planned as an advanced automated warehouse that includes pallet-type & box-type shuttle racking systems and automated guided vehicles (AGVs). With the assistance of automated equipment, the previous worker-to-product work module has been changed to product-to-worker, along with the automated goods yard, logistics boxes for products from different sections are gathered and sent to the packaging yard for packaging. The system recommends the best box number and packaging materials to improve efficiency and reduce packaging material consumption, achieving energy conservation and carbon reduction. The overall number of processed packages per day is expected to be more than doubled, and will effectively solve significant fluctuations in orders. At the same time, big data analysis is used to optimize the division of orders by area and time period to achieve handover between PChome’s own fleet and other logistics providers, so that goods can be delivered to consumers more efficiently. The Linkou A7 Intelligent Logistics Park was fully activated in 2023. It is the first logistics center that incorporates the highest density of AI technologies and fully automated warehouse equipment among e-commerce companies in Taiwan. Shipments accounted for 57% in the fourth quarter of 2023, and the target to account for approximately 60% of shipments has been achieved. In the future, we will continue to increase our shipment capacity. By transferring hot-selling products that can be put into automatic warehouses to the Linkou A7 Intelligent Logistics Park, we will gradually increase the shipment capacity to 70%.

Artist’s Impression of the Smart Logistics Center

Training Program for Nurturing Smart Logistics Talent

In view of the launch of the highly automated warehouse in the smart logistics center, and to prevent the replacement of the workforce stationed at the current warehouses, PChome has organized human resources transformation measures and training programs for the workforce so employees can successfully perform high-quality tasks without losing their positions as a result of automation. This will

improve the process quality and stabilize the reliability of consumers’ shopping experiences. In addition, the workforce could switch to new tasks in which employees create innovative shopping experiences for consumers. The planned PChome training programs include but are not restricted to the following:

• Smart picking system operation training

• Enhancement of inbound product quality management

• Enhancement of product storage management

• Value-adding processes training

• Detection of various task-related anomalies

Green Payment

Digitization of Uniform Invoices

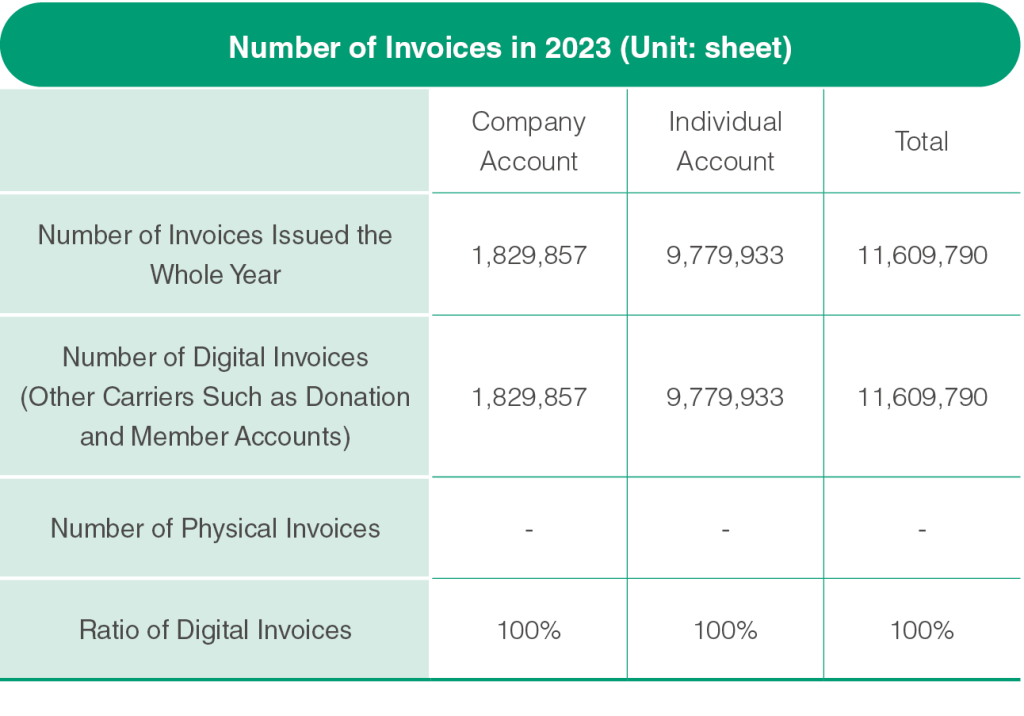

Traditional physical invoices need to consume a massive amount of paper and ink, and become waste after only one use. PChome took it upon itself to apply sustainable practices in consumers’ lives and developed a green e-commerce mode. In October 2005, PChome became the first e-commerce platform to digitize uniform invoices while also obtaining government approval. We actively encouraged consumers to embrace the use of digital invoices. In January 2018, we launched electronic invoices for business entities. Our digital invoice development goals are threefold: to increase the number of digital invoices issued to customers, reduce the number of physical invoices, and to fully adopt digital invoicing during vendor account checking. These measures in general help increase the popularization of digital invoices. This not only reduces the use of paper and ink and help preserve forests but also reduce the generation of waste. It also saves the time and costs for mailing physical invoices and energy consumption for transportation, thus effectively reducing unnecessary carbon emission. In 2023, electronic invoices accounted for 100% of all the invoices. All vendor invoices have been fully converted to PDF files for download, saving over 11.6 million physical invoices, which would measure 2.37 times the height of Taipei 101 (at 509 meters) if piles up.

Cancel Paper Picking Lists, Summary Forms, and Shipment Details

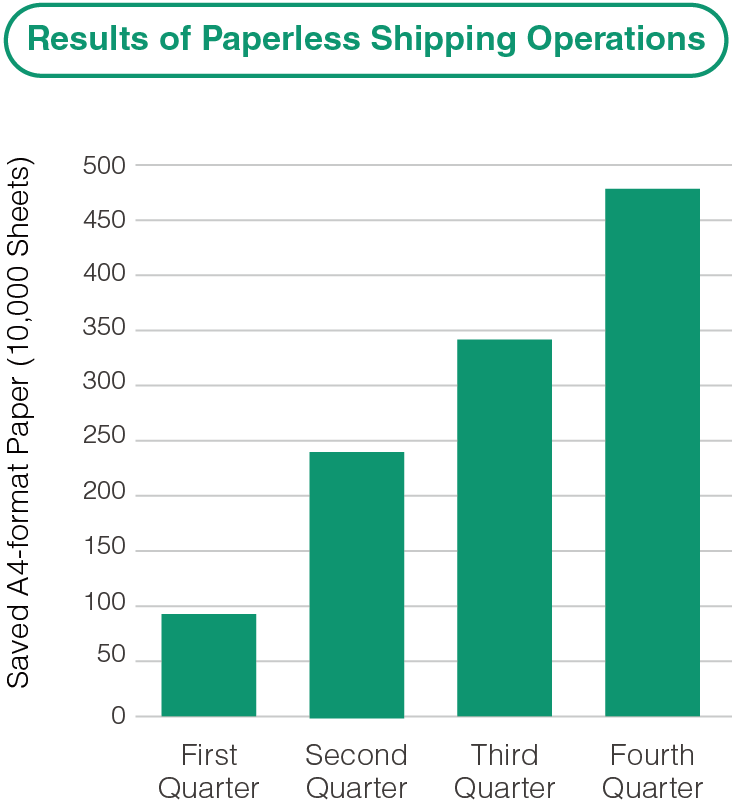

In view of the huge business scale and large shipment demand, PChome realized that if it continued to use traditional paper-based operations, it will consume a lot of paper, incur printing costs, and occupy storage space. In response to this situation, PChome will digitize the “picking list,” “summary form,” and “shipment details” starting from 2023, and display them directly on the screen instead of printing paper information. Through this action, PChome can save 3 sheets of A4 paper per order, significantly reducing paper consumption, thereby reducing the need for deforestation, and helping to protect the environment and reduce carbon emissions. At the same time, electronic operations have shown other advantages. For example, managers can view and analyze picking data in a timely manner, making it easier to manage and track the status of shipping operations. This allows them to quickly understand business operations, make timely adjustments and decisions, and reduce the proportion of human errors. In 2023, PChome electronically processed a total of 37,900 orders, successfully reducing A4 paper use by 11.39 million sheets, which is equivalent to 82,042 kg CO₂e. In the future, we will further reduce paper use by operations and plan to cancel the purchase order QC form at the Linkou A7 Warehouse. The QC forms will be replaced by bound containers. QC information will be displayed directly on the screen based on the PDA operating system, which will reduce paper consumption and improve shipping efficiency.

Paperless Electronic-Tickets and the Establishment of the Electronic Book Section(GRI305-5)

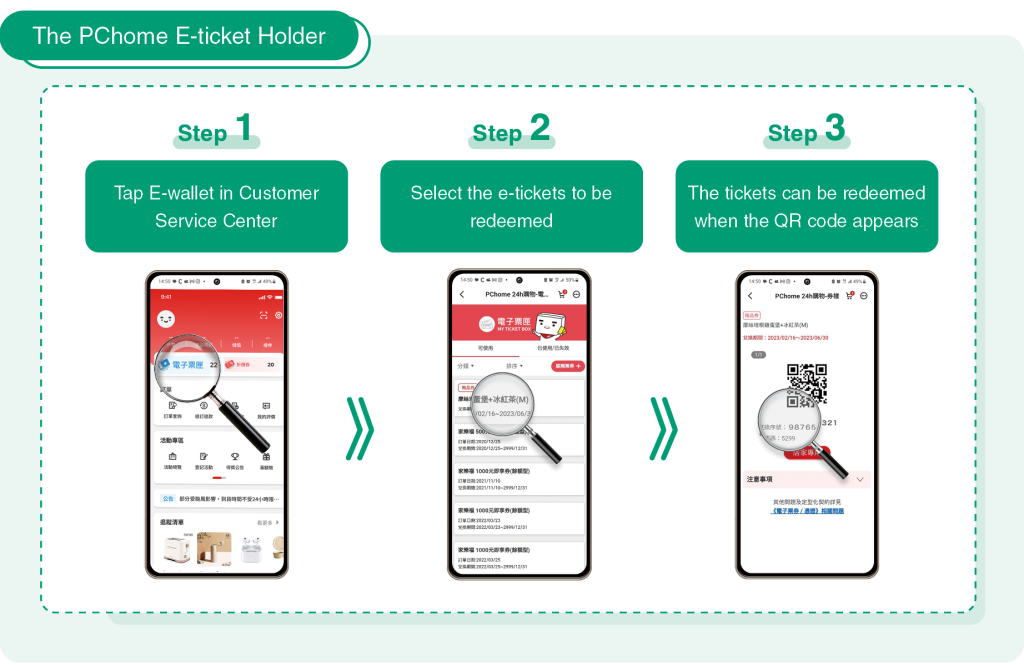

With the popularity of mobile devices, the application of electronic tickets not only brings convenience to consumers, but can also achieve the benefits of reducing paper consumption and reducing carbon emissions. In the light of this, PChome is dedicated to promoting e-tickets and has established an electronic ticket section. After making purchases, consumers open electronic tickets in the electronic ticket folder and present the serial number, bar code, QRcode or certificate to designated vendors for redemption. The total number of tickets sold in 2023 was 624,339, with sales exceeding NT$1 billion. Making these tickets electronic has reduced A4 paper use by over 122,000 sheets in 2023, totaling 882.18 kg CO₂e.

In addition, PChome also established an electronic book section and worked with the domestic electronic book platform Readmoo. In 2023, PChome added a new partner, KOBO, the world’s largest electronic book platform. The number of e-books on the shelves increased by more than 4.8 million in 2023, providing a variety of choices to meet the needs of electronic book users. At the same time, we also adopted KOBO’s international general classification, so that consumers can more conveniently choose their favorite products. Overall, a total of 4,439,061 electronic books were sold in 2023, 50.79 times that of 2022. We hope to continue to increase the variety of products in the future, and encourage vendors to use e-tickets and e-books as the main event tie-ins to guide suppliers to sell products in a more eco-friendly way. We provide diverse options of electronic products for consumers to choose from to develop green consumption habits. This not only significantly reduces the usage of paper, logging of trees, and usage of water resources, but also saves packaging materials and reduces the environmental burden caused by logistics.

Digitalization of Supplier Contracts and Internal Documents

Since 2021, PChome has promoted electronic documents, and the current proportion of electronic signatures has exceeded 70%. Besides reducing the use of paper to achieve carbon reduction benefits, it also speeds up the document approval process. As of the end of 2023, 86,618 forms have used electronic signatures. PChome began to sign electronic contracts with suppliers in 2022. The back-end system will send electronic contracts for suppliers to sign and upload relevant documents. In addition to reducing paper consumption and resource consumption, the transparent approval process allows suppliers to immediately understand the progress, improves the efficiency of contract renewal, and reduces the Company’s operating costs. The number of suppliers that signed an electronic contract in the back-end system reached 2,795 in 2023. After the new version electronic contract was launched in 2024, new contracts were signed with current suppliers starting in April with the target of updating the contracts with 300 suppliers every month.

.jpg)